Wedge Wire Screens

Wedge Wire Screens

Features

- Wedge wire is a welded steel structure, mainly used for filtration.

- It consists of surface profiles, usually V-shaped.

- The distance between the surface profiles is controlled very accurately, as it forms the slot through which the filtrate flows.

- As a result of modern technology of welding, different wires may be used, various slots in one wedge wire screen, as well as different distances between supporting wires can be created.

- It is used for separating solids from liquids, retaining media, filtering, sizing, dewatering, collecting, and distributing.

Advantages

- Non-blocked-up.

- High-precision slot sizes.

- Easy to clean.

- Low pressure-drop.

- Strong construction.

Wedge wire screens are available in a wide variety of shapes and sizes, almost all shapes and sizes can be developed to fit customers´ requirements.

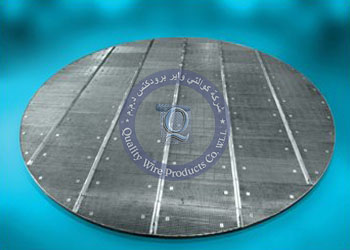

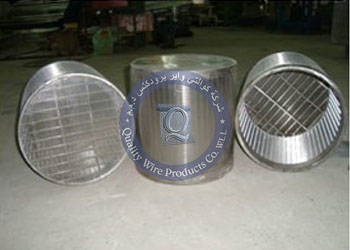

Wedge Wire Screens are V wire screens normally made in tubular form with slot opening from 50 Microns to 25MM opening which are either used in tubular form or cut and levelled and used as flat bed screens.

Manufacturing Process

Wedge wire Screens are manufactured with Triangular Wire rigidly welded to support rods mounted on a circular die and the welding is done with circular disc continuously at each point of contact resulting in forming a tubular form. These tubular form screen can either be used in tubular form or further opened and flattened according to the requirements.

We can offer screens from 12MM diameter till 650MM dia with length of the screens varies from 2.4Mtr to 6Mtr according to the customer requirement.

These screens can be manufactured in Stainless steel 304L & 316L & 904L ; SS321 & SS410 and also in special nickel alloy material like C276; alloy 600 & 800 & duplex and super duplex alloys.

Slot opening range from 50 Microns to 25MM Opening in different models and patterns.

Two typical types can be manufactured one is flow in & flow out (refer images)

Typical End Usage of the screen ( we have to add images)

- Catalyst support screen

- Well Pipe screen

- Screens for sugar and coffee separation

- Flat panel screens with additional reinforcement

- Support grids with additional reinforcement

- Screens for reactors and Molecular sieve

- Header & laterals

- Top Distributor/ Outlet collector/bottom support screens

- Nozzles for charcoal adsorber

- Conical strainer type screens for sugar industries

- Resin trap for stainer housings

Design

Complete design of screens for different application as per customer requirement You explain the type of the plant and give us the requirement & we shall design & offer a complete screening solution.

- Detail engineering calculation involving process and wedge wire design

- Detail support calculation involving the entire load on the screen

- Complete detail drawing keeping the above details in mind

- Step by step installation procedure or onsite installation team

Troubleshooting /support team

A complete team of trained engineers are available for troubleshooting and they can be of great assistance in installation /troubleshooting of screens at site and is available at additional cost depending upon the nature of the project.